Switzerland-based brand, On, has been making enormous leaps in the world of running in recent years. Founded as recently as 2010, On has been growing at an insatiable rate to rival the likes of Nike and Adidas on the world stage. In 2024 it posted record quarterly earnings, and made over 2 billion Swiss Francs (£1.8bn or $2.35bn) revenue in the last 12 months.

Profits over planet

Of course, more revenue is the result of increased sales. We recognise most of us (we see you, barefooters) need shoes in order to run. However, we want to see more people buying shoes made from environmentally-conscious materials and with greater durability.

So far, On has been rather ‘off’ in its sustainability credentials. According to Good on You, On’s sustainability credentials are rated ‘not good enough’: “It uses some eco-friendly [processes] including recycled materials. There is no evidence it reduces its carbon and other greenhouse gas emissions in its supply chain. There is no evidence it minimises textile waste. There is no evidence it implements water reduction initiatives.”

Despite that, On remains one of the few brands to produce a range of fully (or mostly) recyclable shoes – the Cyclon range – which works on a subscription model.

Light at the end of the tunnel?

This is just one way On is starting to innovate in the sustainability space, and their latest innovation is another.

Launching their exciting new upper technology – LightSpray™ – the company boasted a 76% reduction in emissions compared with one of their regular shoes with a standard upper.

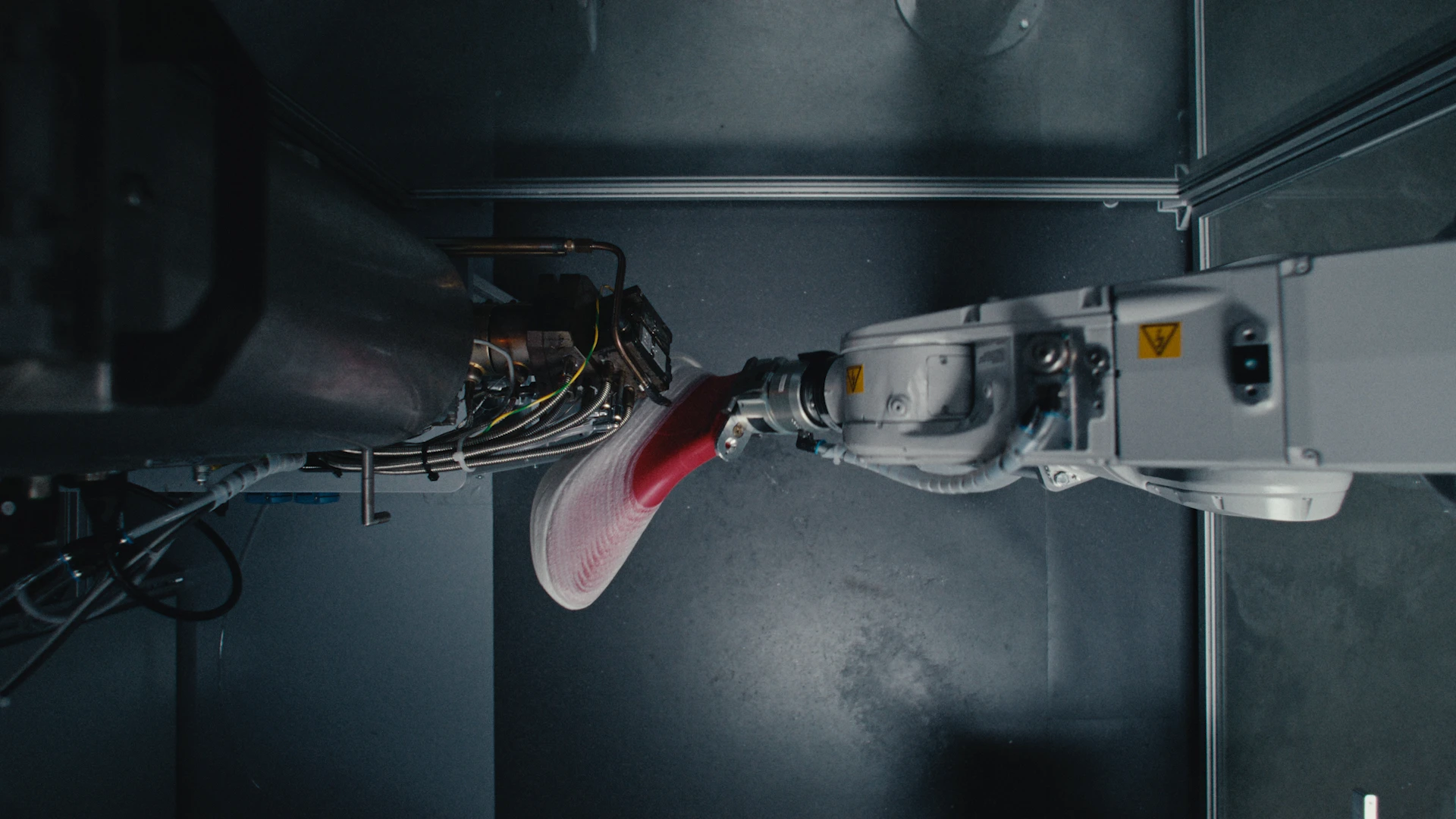

Watching the promotional video is like watching something from the 25th-century, not the 21st. Complete with a rotating robotic arm, the new technology sees the upper sprayed directly onto the last (which gives a shoe its shape) in three minutes. In doing so, On says, it cuts around 200 assembly steps to one.

The whole aim of the new technology is to slash the weight of the upper materials. In doing away with laces, eyelets, overlays, heel counters, insoles and more, the new technology sees the upper weight trimmed to just 30g. On the Cloudboom Strike LS, it reduces the weight of the whole shoe to just 170g.

That’s the kind of weight you need to win the biggest races – or break World Records.

The Good

That all sounds cool, right? But what does that mean from a sustainability standpoint? We had a look through On’s own Life Cycle Assessment (LCA) document (independently produced with Vaayu) for the LightSpray™and here’s what we found.

One assembly step

Assembly lines are costly, but they are also tough on the environment. An assembly line requires multiple individuals to operate, as well as machinery constantly powered to maintain the workflow.

One robot doing all the work reduces the need for all that.

Improved recyclability

One of the tricky things when it comes to recycling footwear is the sheer number of components involved. In order to recycle a shoe, the various materials need to be deconstructed.

In reducing their upper materials to just one part, On has made a shoe that is much easier to recycle at the end of life stage.

Reduced waste

In a typical upper with lots of materials, production creates a significant amount of waste due to off-cuts and mistakes. Every time a new upper is cut, there will be parts left on the cutting table that eventually go to waste.

In the upper, On has reduced the potential waste created. This is largely due to the manufacturing process, but also the fact the technology is being used for just a few athletes and made-to-order. Typically, if a whole shoe is made-to-order (i.e. on-demand) it creates vastly more emissions due to the fact that factories need to power-up machinery for each order, as well as reducing efficiency in the assembly line.

Reduced supply chain emissions

In reducing the components and raw materials required for the upper, On has slashed their supply chain needs for each shoe. One of the reasons carbon accounting and sustainability remain elusive in footwear is the, at times, complex nature of supply chains.

In addition, On has the power to control the energy used to create the upper material, using renewable energy to power the lab and so forth. On alludes to this in the Life Cycle Assessment, suggesting a 78% reduction in emissions from the upper if renewables are used.

Of course, the robot itself and the material it uses to form the upper require materials and, thus, a supply chain, but in the shoe itself the supply chain is much smaller.

The Bad

These are some positive steps, though for every ying there is a yang. For instance, there might be greater transparency and control over the energy used to make the material, but it doesn’t mean clean energy is being used to do so.

This is all to say that, whilst there are good sides there are also some not-so-good.

The upper is just one part

The only part of the process On is claiming to have made the 76% emissions reduction in is in the upper. The rest of the shoe (midsole, insole and outsole) is still made in the ‘normal’ way. This significantly reduces the true carbon emission gains.

According to analysis by Run Repeat, 41% of a shoe’s total carbon footprint is due to the upper material. Applying this to the 76% reduction reduces the overall benefit to just 31%. However, it’s worth noting that 64% of a shoe’s footprint occurs in the manufacturing stages so any technology to improve this is still welcomed.

Interpreting supply chain emissions

Manufacturing produces a large amount of GHG emissions, but not all are created equally. Read an article from Victoria Hatch on net zero in product manufacturing and how emissions are produced at each stage.

Reduced durability

We haven’t had a chance to handle a shoe using the LightSpray™technology yet. However, with reduced weight and overlays often comes reduced durability. The elite, ultra-lightweight, running shoes tend to tear on the uppers much quicker than tougher and heavier shoes.

Whilst emissions per shoe might be reduced, if people are buying multiple shoes the benefits are quickly negated. If the overall life of the LightSpray™upper is reduced by 31%, (say 690 miles of use instead of 1000 miles), suddenly there is no net benefit at all!

When around 22 billion shoes are already sent to landfill every year we need to drastically cut the number we purchase and dispose of, and durability is a big contributor.

Will people actually like it?

On has made it clear in their Life Cycle Assessment document they plan to commercialise the LightSpray™upper and expand it to other shoes in their range. With the reduced structure in their upper, it’s quite likely many people will purchase the shoes due to the hype before finding it doesn’t support them as a runner.

That means a risk of more heading to a trash can.

The commercialisation process

That leads us to the final point: how On will commercialise the process of LightSpray™remains to be seen. They remark in their document they want to retain the benefits from LightSpray™from a carbon perspective.

If they keep the manufacturing in their own labs, upscaling would require more robot arms and space, as well as the shipping of completed outsoles and midsoles to Zurich for completion.

However, manufacturing where the rest of the shoes are made would also be a complicated process, requiring training, shipping (or building) of robots to Asia, and other potential emissions.

Ideally, we’d like to see an updated Life Cycle Assessment once LightSpray™goes global, telling us how the commercialisation affected the environmental benefits and considering the true whole life cycle where durability is a factor.

Our verdict

What On has created has set the cat amongst the pigeons in the high-performance running world. Compared to the likes of Nike and Adidas, On has produced a supershoe with at least some sustainability credentials – something few of the big brands can boast about. Even the fact they have produced a LCA is a big step in the right direction.

Whilst we are pleased to see this kind of innovation supporting the reduced carbon emissions in the footwear industry, we have reservations. There are promising signs from LightSprayTM, but how they upscale the technology and prove its durability are areas to watch out for.